Carbon nanotube products

Packaging

Jar 0.4 L (up to 100 g)

Other packaging volumes are available at customers’ request

Versatile conductive additive for compounding of thermoplastic polyurethane (TPU), filled phenyl polysulfide (PPS), acrylonitrile-butadiene-styrene (ABS), polycarbonate (PC), PC-ABS, polyamide (PA), glass-fiber reinforced polyamide resin (GF PA).

To buy nanotube products, please contact us. Price depends on the required volumes.

Material system

Thermoplastic polyurethane (TPU), filled phenyl polysulfide (PPS), acrylonitrile-butadiene-styrene (ABS), polycarbonate (PC), PC-ABS, polyamide (PA), glass-fiber reinforced polyamide resin (GF PA)

Working dosage

0.5–5 wt.%

Сoncentrate carrier

Polyol ester

Shape

Pellets

Benefits

Electrical conductivity

Permanent and homogeneous electrical conductivity at low dosages

Mechanical properties

Maintained original key mechanical performance

Permanent characteristics

Resistivity is independent of humidity

Less rejection

Less rejected final parts

Cases

Signal lamps

click to view case

Documents

Also available in:

English

TUBALL MATRIX 808 ABS PROCESSING GUIDELLINES ENG V03.PDF

PDF204.8 kB

TUBALL MATRIX 808 GF PA6 PA6.6 PROCESSING GUIDE ENG V04.PDF

PDF204.8 kB

TDS TUBALL MATRIX 808 ENG V09.PDF

PDF102.4 kB

Video

How to grant conductivity to glass fiber reinforced polyamide: compounding guide

News

November 14

Join our webinar on December 5 and gain the latest technical insights on SWCNTs in today’s trending battery technologies. Nanotubes pave the way to long-lasting, silicon-rich (SiOx and SiC) anodes, enable record-thick LFP cathodes for energy storage systems (ESS) and EVs, make it possible to improve the tensile strength and reduce the amount of PTFE in this emerging tech, improve battery cycle life, and lower internal resistance, enabling high-performing electrodes, fast-charging graphite, and single-crystal NCM materials.

Register via the link:

https://events.zoom.us/ev/AsJM4aDgmkugi1bR5OFlW9jPyR92HdeOIMqzi5262YDKXEdDd-yY~ArXTE2RAoIF4YVW0EQis7V2Izp2uj8cK477DYBQAk7rDpL_OOCdeJ4LyYowcwinmRAfWiW8WJdtGvSSxUMkQACiPvQ

Learn more about nanotubes in batteries: https://tuball.com/nanotubes-for/high-performance-ev-batteries?utm_source=facebook&utm_medium=Battery+announcement+%232&utm_campaign=Nov+14%272023

#freewebinar #batteries #EV

Read on Facebook

October 19

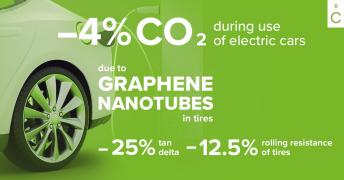

Graphene nanotubes in tire treads can reduce emissions from EV usage by 2–4%. How? Nanotubes add conductivity and make it possible to alter formulations to retain high elasticity in tire treads. This decreases tan delta at 60°C by 15–25%, consequently reducing the rolling resistance coefficient by about 7–12%. Ultimately, this results in 2–4% less emissions during EV usage.

Learn more on graphene nanotubes for elastomers: https://tuball.com/nanotubes-in/elastomers?utm_source=Facebook&utm_medium=GNT+emission+banner&utm_campaign=post+campaign_Oct+19

#EV #tires #emissions #sustainability

Read on Facebook

October 11

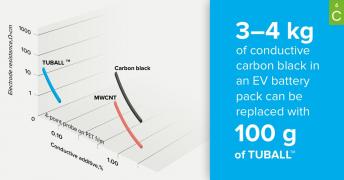

The performance improvements in Li-ion battery cathodes with graphene nanotubes are unmatchable with traditional conductive materials. 🔋 With less than 0.1% TUBALL graphene nanotubes(a concentration 10–60 times lower than is needed with multi wall carbon nanotubes or carbon black), higher energy density is achieved. Intrigued?

Discover more here: https://tuball.com/nanotubes-in/cathodes?utm_source=Facebook&utm_campaign=Post+campaign&utm_term=Oct+11

#Liion #batteries #cathodes #EV

Read on Facebook