TUBALL™그래핀 나노튜브 :고성능

OCSiAl is the global leader in single wall carbon nanotube technologies and the key supplier of nanotube solutions. Explore more than 40 nanotube products for various polymers and electrochemical power sources.

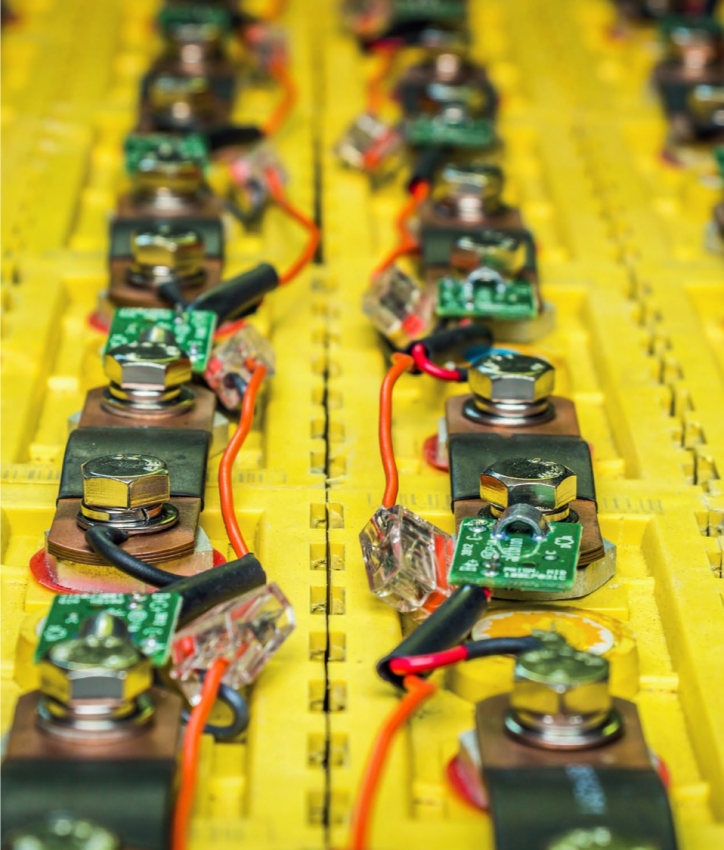

BATTERIESHigh-performing conductive and reinforcing additive for battery electrodesLearn more항공우주 산업그래핀 나노튜브를 이용한 스마트 소재 및 기술자세히 보기오일&가스그래핀 나노튜브는 안전성과 생산성을 보장합니다.자세히 보기모빌리티의 미래나노 복합소재 기술을 이용한 운송수단자세히 보기

애플리케이션 사례

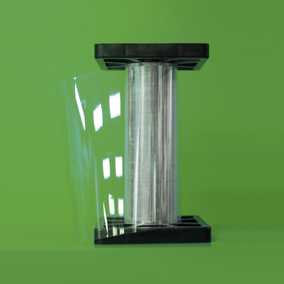

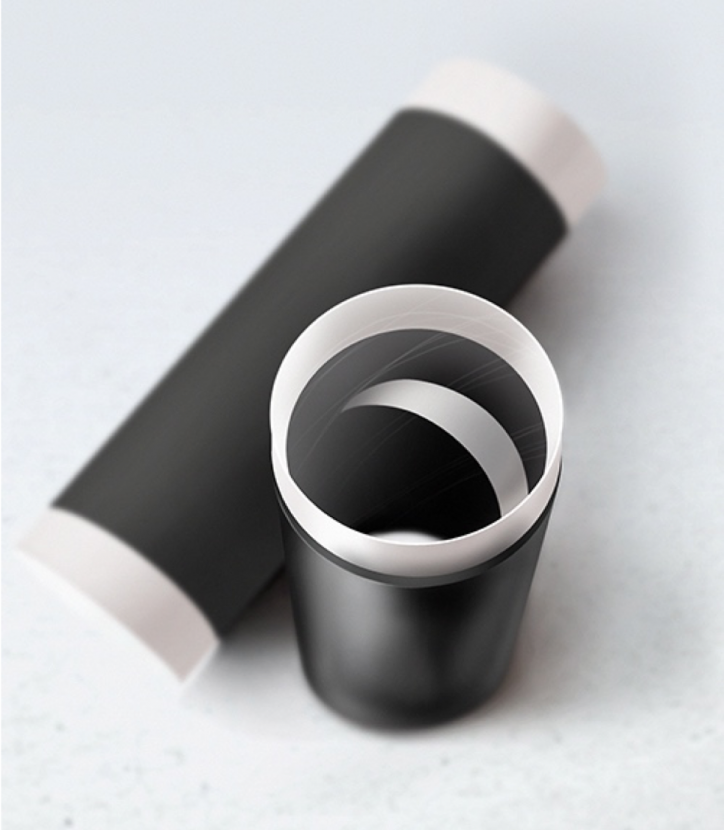

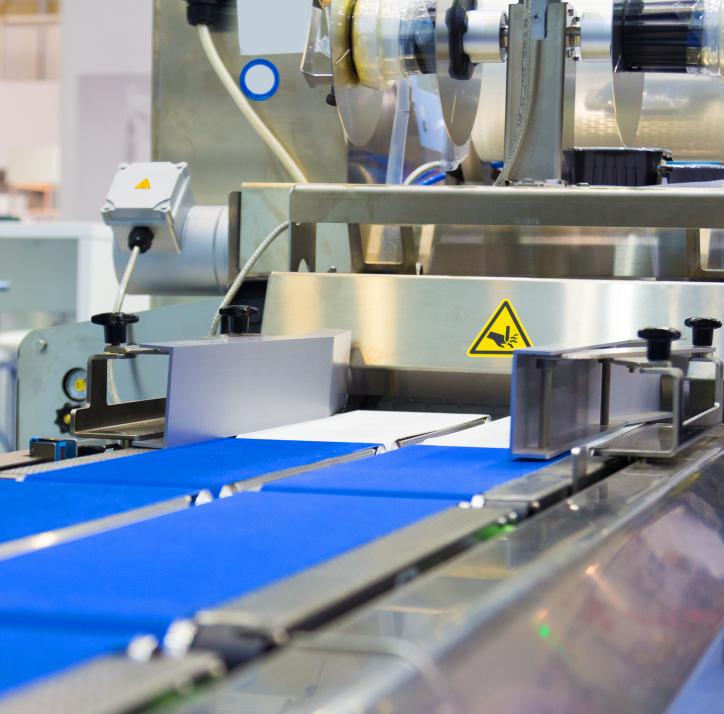

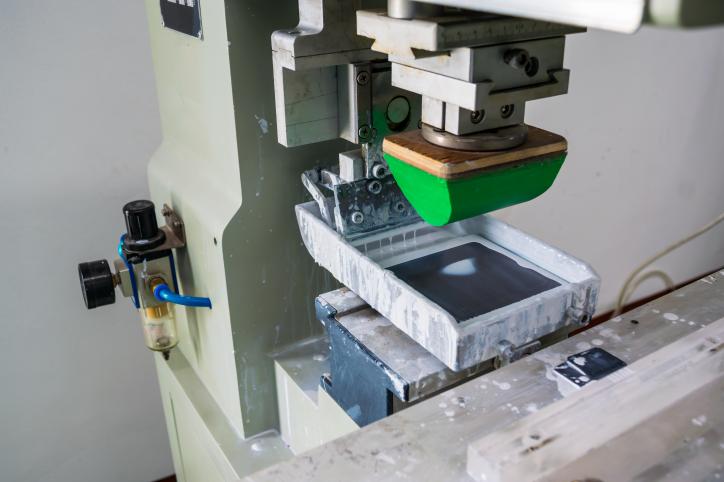

NBR 컨베이어 벨트를 위한 TUBALL™ 그래핀 나노튜브

제품

센서, 인쇄 및 산업용 롤러가 장착된 공장에서 사용되는 NBR 컨베이어 벨트 NBR输送带,用于配备传感器、印刷机和工业滚筒的工厂

요구 물성

- 안정적인 전기 저항성 유지

- 기계적 물성 유지

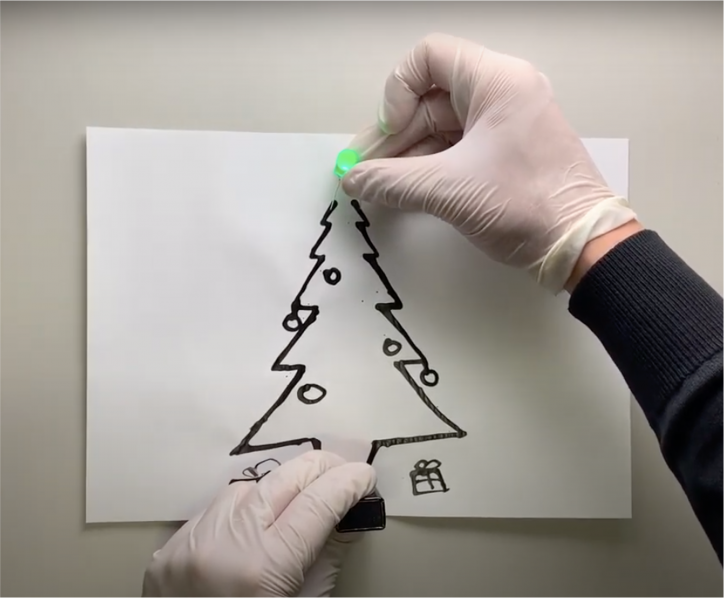

TUBALL™ 적용 제품

3 wt.% TUBALL™ MATRIX 619 beta/623 beta

주요 특징

- 영구적이고 균일한 전기 전도성 구현

- 표면에 카본 이물 방출 현상 없음

- M50: 67% 개선

- M100: 50% 개선

- M200: 30% 개선

- M300: 20% 개선

- 찢김 강도: 35% 개선

- 반발 탄성: 22% 감소

뉴스

2026년 1월 22일

Today in Merl, Luxembourg, the OCSiAl team and those close to him are saying farewell to Alexander Khasin.

Alexander, you are with us. We will do everything we can to ensure that your work and scientific contributions live on.

Read on Facebook LinkedInAlexander, you are with us. We will do everything we can to ensure that your work and scientific contributions live on.