Conductive additive for glass fiber filled PPS compounds with maintained mechanical properties and required processability

TUBALL™ 그래핀 나노튜브는 TUBALL™ MATRIX 821 베타 및 TUBALL™ MATRIX 808 형태의 다목적 전도성 첨가제로, 기계적 특성을 유지하면서도30–50 wt.% 유리 섬유 충전 PPS 화합물(glass fiber filled PPS compounds)에 허용 가능한 주입성을 제공하도록 특별히 설계되었습니다.

열가소성 수지에 사용되는 기존 첨가제는 스펙 오프 제품의 증가로 인하여 제품의 성능을 절충해야 하는 등의 단점이 있습니다.

카본 블랙은 안정적이고 균질한 전기 전도성을 제공할 수 없고, 탄소섬유의 경우는 낮은 저항 목표치를 구현할 수 없습니다.

기존의 첨가제와는 달리, 전체 컴파운드의 0.1wt.%의 소량부터 사용이 가능한 그래핀 나노튜브는 주변 조건에서의 치수 안정성을 포함하여 고함량 GF가 포함된 PPS에서 탁월한 화학적 및 열적 성능을 보존할 수 있습니다. 또한 MFI, 충격 및 점도에서 타겟 성능을 유지하여MWCNT로 달성하기 어려운 물성을 구현합니다.

CONDUCTIVITY, PROCESSABILITY, MECHANICAL PERFORMANCE

Graphene nanotubes’ unique morphology allows them to create a dense conductive network inside thermoplastic compounds at low loading rates—starting from 0.1 wt.% in the total compound.

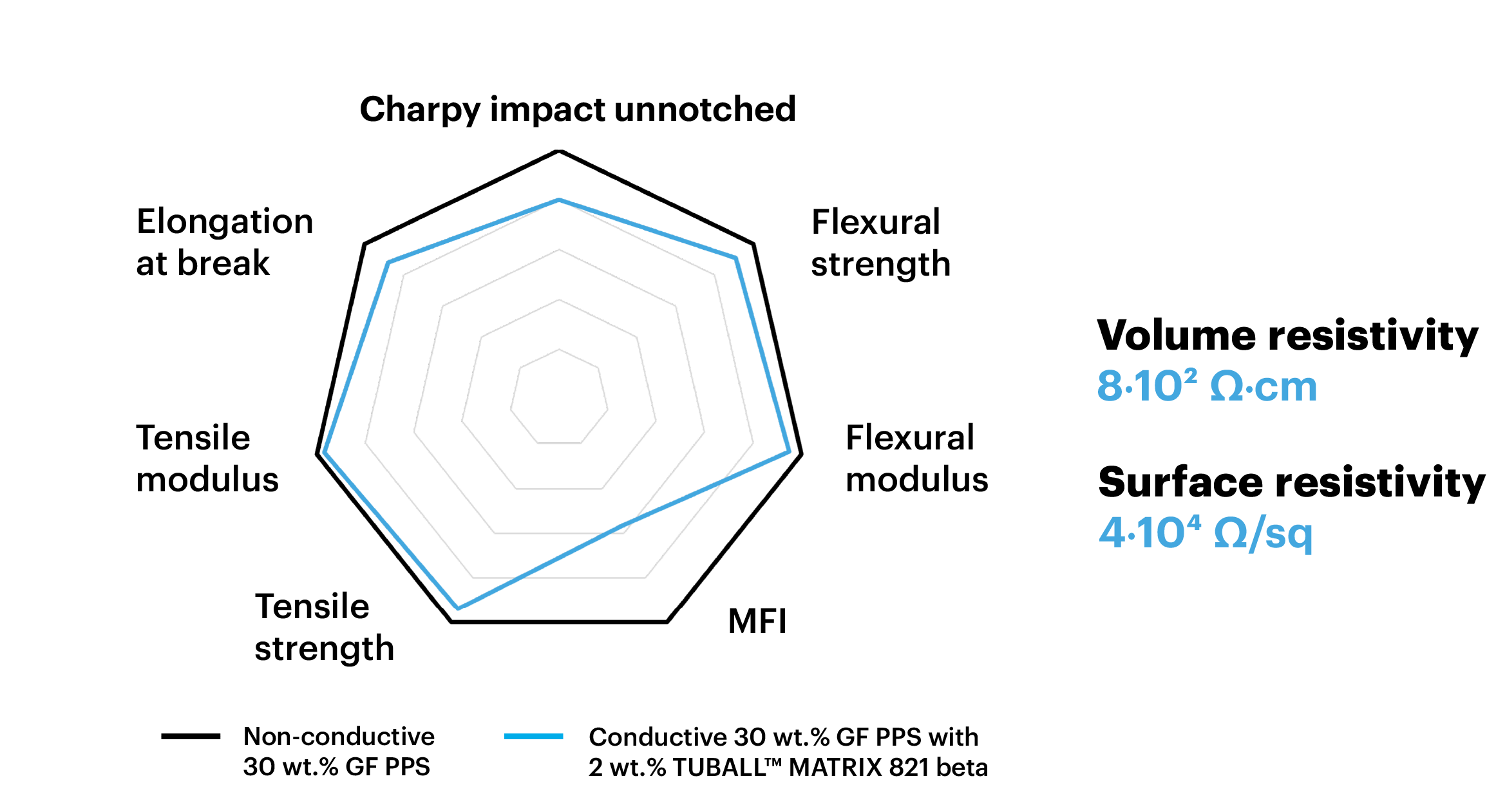

The use of TUBALL™ MATRIX preserves key mechanical properties and provides acceptable injectability.

Case: 2 wt.% TUBALL™ MATRIX 821 beta (0.2 wt.% TUBALL™ nanotubes) in 30 wt.% glass fiber filled PPS.

*OCSiAl internal study. Results may vary depending on the formulation, processing, and products.

전도성 GF-PPS 컴파운드는 전기차 배터리 셀용으로 사용되는 전도성 캡을 포함하여 다양한 건축 및 자동차 부품 제조에 사용됩니다.

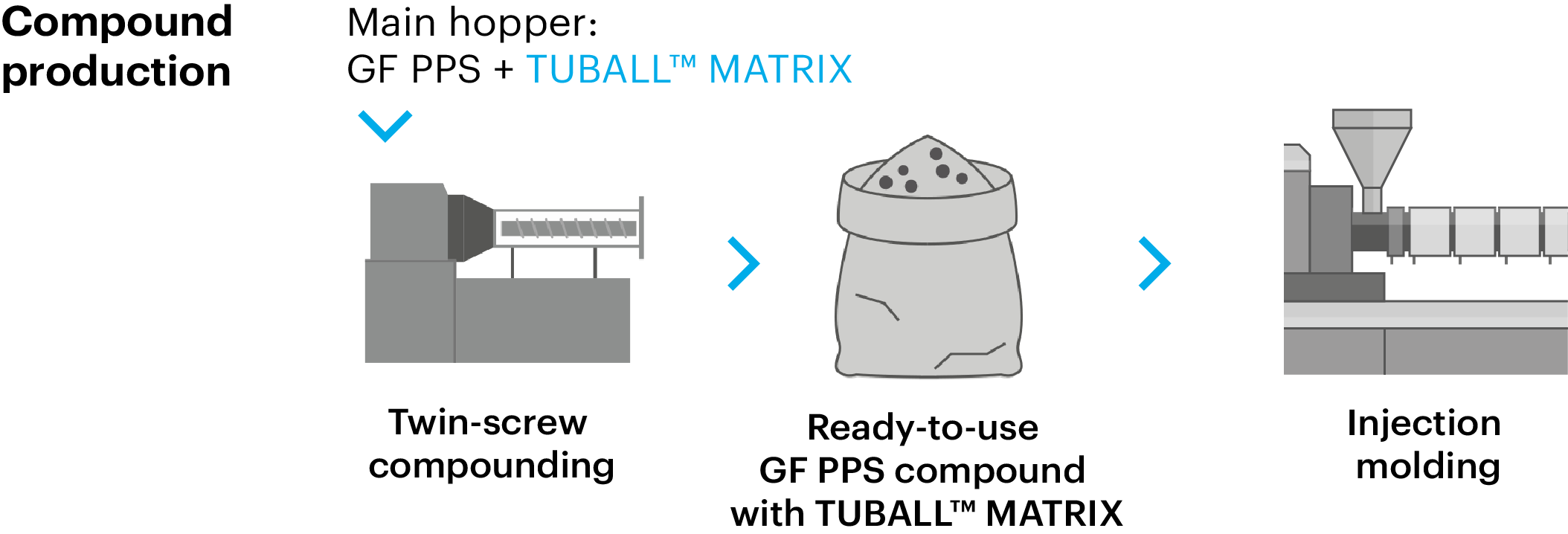

EASY-TO-APPLY WITH STANDARD EQUIPMENT

TUBALL™ MATRIX can be processed with standard equipment widely used in the thermoplastics industry.

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample